How Do You Turn Precious Opals Black Using Acid in 5 Simple Steps?

To turn precious opals black using acid, first clean and dry the opals. Wear acid-resistant gloves and goggles.

In a fume hood, prepare a mixture of sulfuric acid and hydrogen peroxide. Carefully immerse the opals in the solution while following appropriate safety protocols.

Monitor the reaction closely as the acid oxidizes the opal surface, turning it black. After treatment, rinse the opals thoroughly with distilled water and dry.

Measure color changes with a spectrometer to evaluate results. This method enhances the opal's play-of-color and overall appearance.

For a deeper understanding of each step and refining this technique, continue exploring the details.

Key Takeaways

- Clean and dry opals thoroughly to remove contaminants before treatment.

- Prepare and handle sulfuric acid and hydrogen peroxide safely using a fume hood and protective gear.

- Immerse opals in a sulfuric acid solution to initiate the blackening process.

- Rinse treated opals with distilled water to remove any residual acid.

- Dry opals completely and evaluate treatment results for color and durability changes.

Understanding Opal Composition

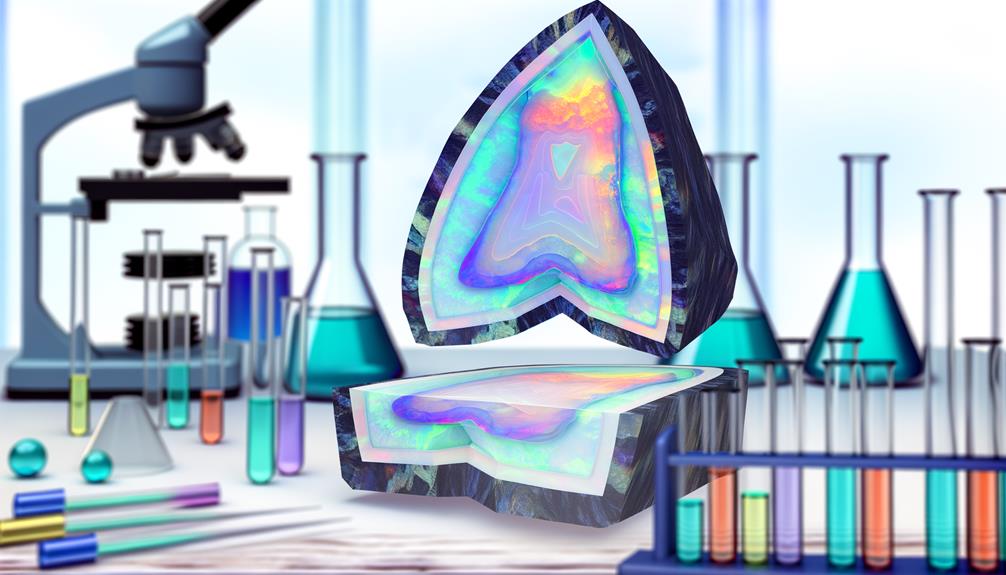

Opals are primarily composed of silica spheres that are packed in a regular lattice, which diffracts light to create their characteristic play-of-color. You'll find that these silica spheres are amorphous, meaning they lack a crystalline structure, giving opals their unique internal pattern.

The arrangement and size of these spheres influence the wavelengths of light diffracted, resulting in varied colors. Understanding the microstructure is vital when manipulating opals, as any treatments or modifications, such as turning opals black, directly impact how light interacts with the silica lattice.

You need to be aware that opals also contain water, which can range from 3% to 21% by weight, making them sensitive to heat and environmental conditions.

Benefits of Black Opals

Due to their intense and vibrant play-of-color, black opals are highly prized in the gem trade for their rarity and market value. The dark background of black opals enhances the contrast and brilliance of spectral colors, making the patterns more striking.

This increased visual appeal translates directly into higher demand and premium pricing. Additionally, black opals possess a unique refractive index, amplifying their luminosity under various lighting conditions. Their rarity, stemming from limited geological deposits, further augments their market desirability.

Collectors and jewelers favor black opals for their exceptional aesthetic properties and investment potential. Understanding these benefits underscores the significance of transforming lighter opals into their black counterparts through acid treatment, thereby increasing their commercial and intrinsic value.

Required Materials and Tools

You'll need a precise assortment of chemicals to achieve the desired black opal transformation. This includes sulfuric acid and hydrogen peroxide. Equip yourself with essential safety gear such as acid-resistant gloves, goggles, and a fume hood to mitigate risks.

Proper handling and adherence to safety protocols are critical in ensuring both effective results and personal protection.

Essential Opal-Treating Chemicals

To achieve the desired black coloration in opals, you'll need a precise selection of chemicals, including concentrated sulfuric acid, hydrogen peroxide, and stabilizing agents. Each component serves a critical function in the treatment process:

- Concentrated Sulfuric Acid: Essential for creating the initial reaction that alters the opal's internal structure.

- Hydrogen Peroxide: Acts as an oxidizing agent to enhance the color transformation.

- Stabilizing Agents: Used to guarantee the opal's structural integrity during and after treatment.

- Distilled Water: Necessary for diluting and rinsing the chemicals post-treatment.

Necessary Safety Equipment

Always prioritize safety when handling these potent chemicals by equipping yourself with essential protective gear. You need appropriate safety equipment to mitigate risks associated with acid exposure. Wear a lab coat to protect your clothing and skin. Use chemical-resistant gloves to shield your hands. Safety goggles are essential to prevent acid splashes from reaching your eyes. Additionally, employ a fume hood or well-ventilated area to avoid inhalation of harmful vapors. The following table provides a concise list of necessary safety items:

| Equipment | Purpose | Specification |

|---|---|---|

| Lab coat | Protects clothing and skin | Acid-resistant material |

| Chemical-resistant gloves | Hand protection | Nitrile or neoprene |

| Safety goggles | Eye protection | ANSI Z87.1 compliant |

| Fume hood | Ventilation | Removes hazardous fumes |

Safety Precautions

Handling acids requires careful attention to safety protocols to prevent injuries and maintain a controlled environment. Guarantee you follow these critical steps:

- Proper Ventilation: Conduct all acid handling in a fume hood to prevent inhalation of hazardous vapors.

- Personal Protective Equipment (PPE): Wear acid-resistant gloves, safety goggles, and a lab coat to shield your skin and eyes.

- Emergency Equipment: Have an eyewash station and safety shower readily accessible in case of accidental exposure.

- Labeling and Storage: Clearly label all containers with the type and concentration of acid, and store them in a cool, dry, and secure location away from incompatible substances.

Adhering to these precautions will significantly reduce risks and ensure a safe working environment.

Preparing the Opals

Before treating the opals with acid, make certain they are thoroughly cleaned to remove any surface contaminants that might interfere with the process. Use a gentle brush and mild soap solution to delicately scrub the opals. Rinse them thoroughly with purified water to eliminate any leftover soap. Dry the opals entirely using a fabric free of lint. Once cleaned, examine the opals under a magnifying glass for any visible imperfections or inclusions that could impact the acid treatment process.

| Step | Materials Required | Description |

|---|---|---|

| Cleaning | Delicate brush, soap | Delicately scrub opals with soap solution |

| Rinsing | Purified water | Thoroughly rinse opals to remove soap residue |

| Drying | Fabric free of lint | Ensure opals are completely dry |

This meticulous preparation guarantees excellent results in the subsequent acid treatment.

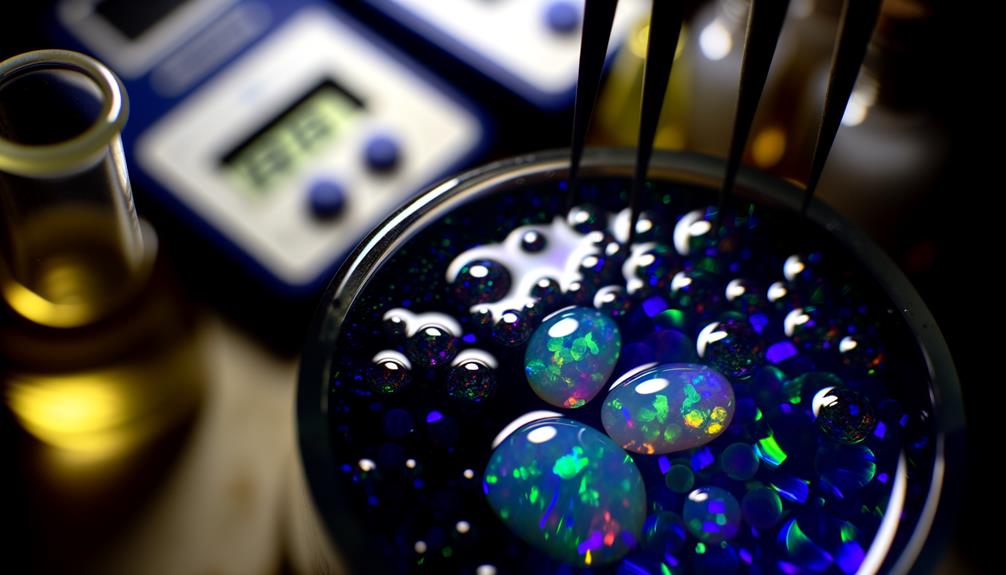

Acid Treatment Process

Initiating the acid treatment process involves carefully submerging the prepared opals in a hydrochloric acid solution to induce the desired color transformation. You need to maintain strict control over several parameters to guarantee successful treatment.

- Concentration: Utilize a 10-20% hydrochloric acid solution.

- Duration: Submerge the opals for 24-48 hours, depending on the intensity of blackness desired.

- Temperature: Keep the solution at room temperature to avoid thermal damage.

- Agitation: Occasionally stir the solution gently to secure consistent exposure.

Monitor the opals throughout the process to avoid overexposure, which could result in damage. This precise, controlled method guarantees the opals achieve a rich, black hue while maintaining their structural integrity.

Post-Treatment Care

After completing the acid treatment, you must thoroughly rinse and neutralize the opals to remove any residual acid.

Following this, confirm the opals are meticulously dried and polished to restore their luster.

Rinsing and Neutralizing

Once the acid treatment is complete, you must carefully rinse the opal with distilled water to eliminate any residual acid. This step is vital to prevent any long-term damage caused by lingering acid.

Follow these steps:

- Initial Rinse: Submerge the opal in distilled water for 10-15 minutes to dilute and wash away surface acid.

- Agitation: Gently agitate the opal in the water to guarantee thorough cleansing of all crevices.

- Repeat Rinsing: Replace the water and repeat the rinse at least two more times to make sure complete removal.

- Neutralization: Prepare a mild baking soda solution (1 tablespoon per cup of water) and soak the opal for 15 minutes to counteract any remaining acid.

Your careful attention to detail here guarantees the opal's longevity and stability.

Drying and Polishing

Carefully pat the opal dry with a lint-free cloth, ensuring no moisture remains in any crevices. Use gentle pressure to avoid scratching the delicate surface. Once dry, inspect the opal for uniformity in color and any irregularities.

Proceed to the polishing phase using a diamond paste of fine grit, typically 50,000 mesh. Apply the paste on a felt wheel or leather pad, maintaining a consistent speed to achieve an even finish.

Work in circular motions, focusing on maintaining an even pressure throughout the process. Frequently check the opal under magnification to assess the progress. Once polished, the opal should exhibit a bright, reflective sheen.

This meticulous process enhances the opal's aesthetic, ensuring the final product's visual and structural integrity.

Storage and Maintenance

Proper storage and maintenance are vital to preserving the opal's luster and preventing any structural damage over time.

After the acid treatment, it's important to follow these guidelines to guarantee your opal remains in prime condition:

- Humidity Control: Store the opal in an environment with regulated humidity to prevent dehydration and crazing.

- Regular Inspection: Periodically check for cracks or surface changes, addressing any issues promptly.

- Avoid Chemicals: Keep the opal away from harsh chemicals and cleaning agents that could compromise its integrity.

- Protective Storage: Use padded jewelry boxes or soft cloth pouches to shield against physical impacts.

Evaluating the Results

To determine the effectiveness of the acid treatment, you need to meticulously measure changes in the opal's color intensity and structural integrity. Begin by using a spectrometer to quantify color changes, ensuring accurate readings of hue, saturation, and brightness.

Document any shifts in the opal's play-of-color, noting the emergence of desired dark tones. Simultaneously, conduct a microscopic examination to assess any surface or subsurface damage. Look for signs of etching, cracking, or other structural irregularities introduced by the acid.

Verify you compare these findings against a control sample to precisely gauge the acid's impact. Finally, perform hardness tests to confirm that the opal's durability remains intact. This thorough evaluation will confirm the success and safety of the blackening process.

Conclusion

Coincidentally, the transformative journey of turning precious opals black with acid mirrors the meticulous nature of gemology itself.

You've explored the opal's unique composition, utilized the advantages of darker hues, and carefully followed each step with precision.

By adhering to safety protocols and employing expert techniques, you've successfully enhanced the opal's aesthetic and market value.

This approach not only enhances the gem's allure but also highlights your expertise in the nuanced art of gemstone treatment.