How to Use Dopping Stick and Wax Safely with Ethiopian Opal

Yes, you can utilize a dopping stick and wax on Ethiopian opal, but careful handling is essential. The dopping stick enhances stability and precision during cutting and polishing, while wax provides strong adhesion and malleability.

However, you must control the temperature meticulously to prevent thermal stress, cracking, or hydration loss. Preheat the opal gradually to align with the wax's thermal properties and apply a thin wax layer for better adhesion.

Selecting high-quality, low melting point wax and avoiding prolonged heat exposure guarantee the opal's structural integrity. With these techniques, you can maximize the opal's potential and maintain its integrity.

Key Takeaways

- Dopping sticks provide stability and precision in shaping Ethiopian opals, making them a suitable tool for gem processing.

- Using wax with a low melting point minimizes thermal stress, reducing the risk of opal cracking.

- Gradually preheating the opal to the wax temperature ensures proper adhesion and reduces the likelihood of damage.

- High-quality wax enhances precision and holds the opal securely during intricate cutting and polishing.

- Avoiding prolonged heat exposure and maintaining controlled temperatures prevent structural deformation and color loss in Ethiopian opals.

Understanding Ethiopian Opal

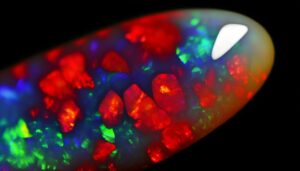

How do the unique geological conditions of Ethiopia contribute to the formation of its distinct and highly prized opals?

In Ethiopia, opals primarily form in volcanic environments, where silica-rich solutions infuse volcanic ash layers. You'll find that the high geothermal activity accelerates the silica deposition process.

These opals exhibit a remarkable play-of-color due to the orderly arrangement of silica spheres. The intense heat and pressure conditions create microfractures, filled with secondary minerals, enhancing the opal's structural integrity and visual characteristics.

Additionally, the presence of iron oxides imparts a range of vibrant hues, making Ethiopian opals distinct. Understanding these geological nuances helps you appreciate why Ethiopian opals are so unique and valuable in the gemstone market.

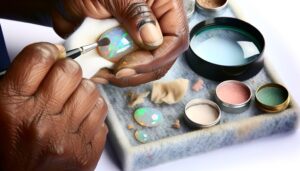

The Role of Dopping Stick

A dopping stick's role in gem cutting is vital for securely holding Ethiopian opal during the intricate shaping and polishing processes. By using a dopping stick, you can achieve greater precision and control, minimizing the risk of damaging this delicate gemstone.

Here's why it's essential:

- Enhanced Stability: It provides a steady grip, preventing slippage.

- Improved Accuracy: Allows for finer, more detailed work.

- Reduced Strain: Eases hand fatigue by offering better leverage.

- Safety: Minimizes the chances of chipping or cracking the opal.

Benefits of Using Wax

While the dopping stick provides stability and control, using wax offers additional benefits by securely adhering the Ethiopian opal to the stick, ensuring it remains fixed during the cutting and polishing. Wax creates a robust bond that accommodates the unique thermal and mechanical properties of opal, preventing lateral movement and enhancing precision. Additionally, wax's malleability allows you to fine-tune the alignment of the opal, ensuring optimal orientation for each cut.

| Benefit | Description |

|---|---|

| Strong Adhesion | Secures opal remains fixed during operations |

| Thermal Compatibility | Matches opal's thermal expansion, reducing stress |

| Malleability | Allows fine-tuning of opal alignment |

| Enhanced Precision | Prevents lateral movement, improving cutting and polishing accuracy |

| Easy Removal | Can be softened and removed without damaging the opal |

Utilizing wax maximizes control, precision, and safety in your gemstone processing.

Potential Risks Involved

Despite the numerous advantages of using wax, you must consider potential risks such as thermal degradation, which can compromise the integrity and stability of the Ethiopian opal during processing. This gemstone is particularly sensitive to heat fluctuations, making it vulnerable to damage.

Key risks include:

- Cracking: Sudden temperature changes can cause microfractures, leading to larger cracks.

- Color Loss: Excessive heat might alter or fade the opal's vibrant colors.

- Structural Deformation: Heat can weaken the opal's internal structure, causing warping.

- Hydration Loss: Ethiopian opals contain water; high temperatures can cause dehydration, resulting in brittleness.

Understanding these risks is essential to preserve the gem's quality and prevent any irreversible damage during dopping.

Best Practices and Tips

To sustain the Ethiopian opal remains intact during processing, attentively control the temperature and use a high-quality dopping wax with a low melting point. This reduces thermal stress, preventing fractures.

Preheat the opal gradually to match the wax's temperature, mitigating thermal shock. Employ a thin layer of wax to enhance adhesion without excessive heating. Monitor the wax consistency; it should be pliable yet firm.

Avoid prolonged exposure to heat sources, as Ethiopian opal is hydrophane and can absorb moisture, altering its integrity. Utilize a stable dopping stick to secure precise alignment.

During finishing, gently remove the wax using a solvent like acetone instead of forceful prying. This method preserves the opal's structural and aesthetic qualities.

Conclusion

To sum up, using a dopping stick and wax on Ethiopian opal can enhance precision, increase control, and improve overall lapidary outcomes. However, it also poses risks like thermal shock and wax residue.

To mitigate these, maintain consistent temperatures, use high-quality wax, and clean thoroughly.

By understanding Ethiopian opal's unique properties, employing meticulous techniques, and adhering to best practices, you can effectively work with this delicate gemstone while minimizing potential damage.