COMING SOON: Objects for meditation and contemplation

COMING SOON: Objects for meditation and contemplation

First release

A small number of portals will be available in our first edition.

The first Opal Portal collection explores two states of being: stillness and emergence. Each piece is designed as a contemporary portal,

a physical object that shifts attention and atmosphere.

Portal I - Primordial Space

A meditation blanket representing origin and stillness. A quiet field before movement begins.

Made from 100% Merino wool

Size: 100 × 70 cm

Manufactured in Germany

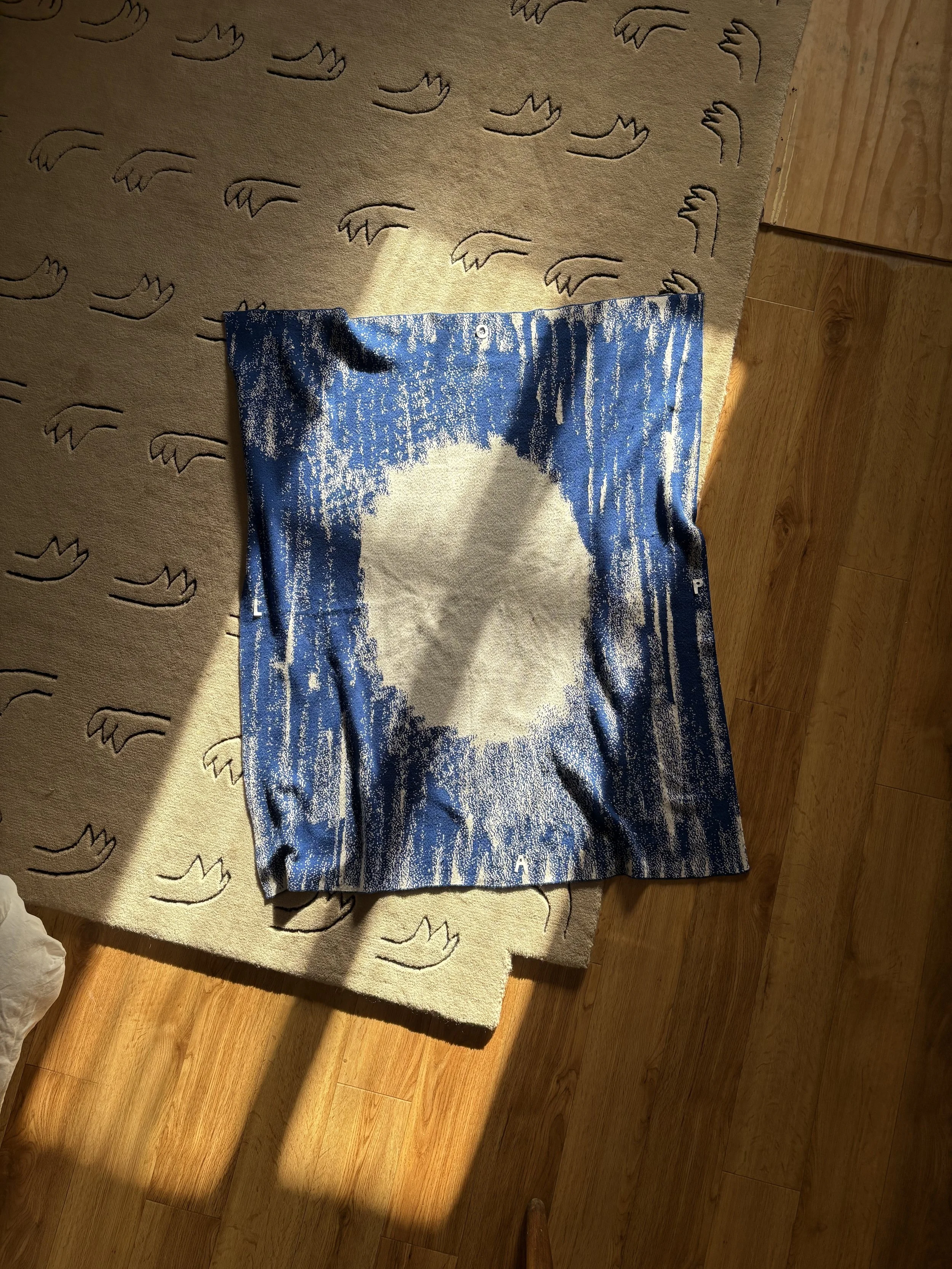

Portal II - Infinite Potentiality

A meditation blanket representing emergence and activation. Energy, direction, expansion.

Made from 100% organic cotton

Size: 100 × 80 cm

Manufactured in Germany